Reduced Measurement Range Redefines Bosch Laser Precision

Reduced Measurement Range Redefines Bosch Laser Precision - Precision Through Deliberate Constraint

The concept of "Precision Through Deliberate Constraint" introduces a provocative reevaluation of how accuracy is pursued in technological design. Traditionally, engineering endeavors often sought wider operational parameters, assuming greater versatility. However, this emerging philosophy posits that deliberately narrowing a system's scope, particularly in measurement, can paradoxically unlock superior precision. It suggests a departure from the "more is better" mindset, proposing that finely tuned, restricted capabilities might outperform broadly adaptable ones in specific contexts. This shift compels an examination of the fundamental trade-offs inherent in design, particularly the tension between expansive functionality and ultimate exactitude.

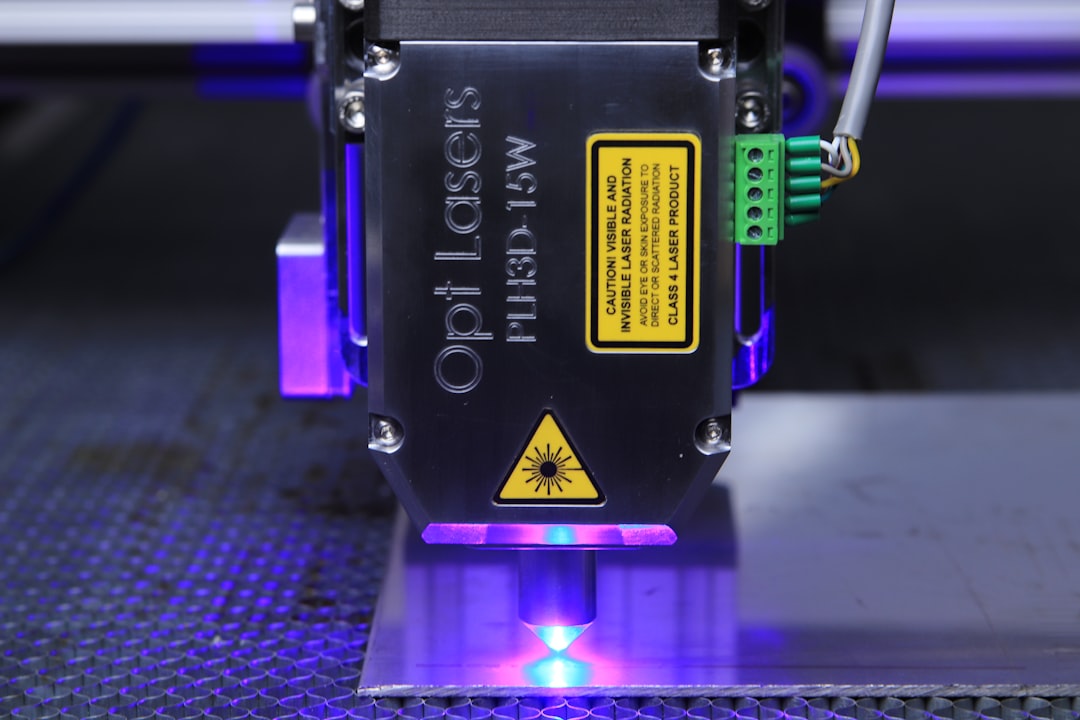

The adoption of a deliberately restricted operational envelope presents several interesting implications for optical measurement systems. This approach inherently manages beam characteristics; for instance, laser beam divergence becomes far less problematic over such a reduced span. This means the energy landing on the detection surface is more concentrated and maintains higher spatial integrity, fundamentally enhancing the signal clarity and therefore the certainty of position determination.

Furthermore, by confining the measurement domain, the system can effectively reallocate its available detector resolution to a much tighter physical region. This is analogous to cropping a high-resolution image to zoom in on a small detail – the fixed number of sensing elements now span a significantly smaller physical area, allowing for much finer discrimination of minute variations or subtle shifts. This concentration of sensing capability can be a powerful lever for precision.

From a mathematical modeling perspective, the advantages are also considerable. The complex equations typically required to account for optical path deviations and component non-linearities over a broad range can be substantially simplified within a constrained operating window. This often translates to more straightforward and robust calibration procedures, potentially requiring fewer data points and less computationally intensive algorithms. While simplifying models is generally beneficial, the real test lies in ensuring that these simplifications do not inadvertently mask critical system behaviors or introduce new subtle errors.

Moreover, operating within such defined limits offers unparalleled opportunities for active thermal management of the laser source and primary optical elements. Mitigating temperature-induced wavelength drift and focal plane shifts – common sources of error in many optical systems – becomes much more achievable. This level of environmental control is crucial for consistent performance, although the energy expenditure and engineering complexity required to maintain such tight thermal stability are factors that must be carefully considered.

Finally, a significantly shortened optical path inherently supports a much higher degree of laser coherence. This opens the door to employing advanced interferometric or phase-based measurement techniques that rely on stable wave interference patterns. These methods promise extremely high resolution but are typically impractical for systems covering wide measurement ranges due to the rapid loss of coherence. This focused approach could enable their practical application in areas where such high precision was previously unattainable outside of a laboratory environment.

Reduced Measurement Range Redefines Bosch Laser Precision - A Strategic Narrowing of Market Focus

Building on the technical insights derived from prioritizing "Precision Through Deliberate Constraint," "A Strategic Narrowing of Market Focus" signals a distinct shift from engineering principles to market positioning. This concept delves into how companies translate highly specialized technical capabilities, like those achieved through a reduced measurement range, into a deliberate market strategy. It prompts an examination of why an entity might choose to concentrate its refined precision on particular, perhaps niche, applications, rather than attempting to serve a broader spectrum of uses. This strategic pivot invites critical inquiry into the trade-offs between excelling within a confined domain and maintaining broader market adaptability, posing questions about long-term growth trajectories and responsiveness to evolving industry demands.

The strategic decision to narrow the market focus appears to leverage a fundamental shift in component selection. Instead of engineering versatile, broadly capable components, this approach seemingly permits the use of highly specialized elements precisely optimized for a reduced operational window. The expectation by mid-2025 is that such tailored componentry will lead to efficiencies in manufacturing processes and material utilization due to the tightly defined performance requirements. However, one might reasonably question whether this high degree of specialization inadvertently creates a dependence on a very specific set of suppliers or technological paths, potentially limiting a system's future adaptability should the target application evolve even slightly.

From a purely technical perspective, confining the operational range to specific, highly demanding applications theoretically allows for an unparalleled dedication to maximizing precision within those very bounds. This goes beyond mere market positioning; it suggests an intensive engineering effort aimed at mitigating every conceivable error source pertinent to that specific scenario. The aim is that by mid-2025, the cumulative expertise and bespoke engineering applied to these constrained niches could manifest as a genuine technical superiority, making it challenging for more generalized solutions to rival the exactitude offered in these specialized domains. The real test, of course, is discerning whether this perceived leadership is a direct outcome of truly superior engineering or simply the result of competing in a less crowded, highly specific field.

A compelling engineering argument for this focused design is the potential for significantly accelerated development cycles. By drastically reducing the number of variables, boundary conditions, and conflicting optimization goals, the phases of design, simulation, and testing could indeed become much more streamlined. This inherent efficiency in the development process suggests that highly specialized, precision tools could be brought to fruition and refined much more rapidly. Furthermore, this streamlined approach implies a simplified end-user experience; within their predefined, narrow scope, these systems could potentially be robustly pre-calibrated and delivered with minimal setup requirements. One might, however, ponder if this push for rapid deployment and simplified user interaction inadvertently curtails access to deeper diagnostic capabilities an engineer might otherwise desire, or if it merely shifts complexity from the operational environment back into the manufacturing process.

The reliance on highly specialized components also naturally fosters very close relationships with specific manufacturers and material suppliers. This isn't solely about cost efficiency; it's intrinsically linked to the collaborative development of bespoke parts and processes essential for achieving the required precision within the narrow scope. By 2025, this could translate into a deeply integrated supply chain where technical insights are shared, and component quality is meticulously controlled from inception. Such a tightly knit relationship, while potentially leading to more robust and reliable finished products, also carries inherent risks, such as an over-reliance on a limited number of key partners, which could potentially limit the exploration of alternative innovations or introduce vulnerabilities if a critical supplier faces unforeseen challenges.

Reduced Measurement Range Redefines Bosch Laser Precision - Mapping Bosch’s Evolving IP Landscape

As of July 2025, Bosch's evolving intellectual property landscape appears notably influenced by its strategic commitment to highly specialized technologies, especially within laser precision systems. This deliberate narrowing of measurement capabilities, while enhancing product accuracy, concurrently reshapes the company's innovation focus and how it cultivates its patent portfolio. Such a concentrated approach naturally raises questions about the long-term viability of an intellectual property strategy centered on deep, yet confined, expertise in a rapidly changing market. The delicate interplay between engineering for extreme precision and a focused market position inherently creates tension regarding adaptability and future growth. This is further complicated by the apparent reliance on specific, highly specialized suppliers, which, from an IP perspective, can lead to intertwined intellectual property development, potentially creating a subtle form of dependence rather than fostering independent exploration. The ongoing challenge for Bosch will be to sustain technical superiority within these specialized domains while ensuring its broader intellectual assets remain agile enough to navigate unforeseen technological shifts.

An interesting development by mid-2025 is the nature of Bosch’s intellectual property filings related to these precision systems. One might have anticipated a vast array of highly specific, niche patents tailored to individual applications or components. Yet, observations suggest that by deeply optimizing systems for confined operational boundaries, they are unexpectedly securing what appear to be more foundational patents covering entirely novel measurement *methods*. These aren’t just patents on an apparatus; they delve into the core principles of achieving extreme exactitude within these narrow windows. While the initial application might be constrained, the underlying methodological innovation often possesses a surprising breadth of potential utility across similar physical measurement domains. This raises the intriguing question of whether such focused development inadvertently unearths deeper, more generic principles applicable beyond the initial intent.

Another noteworthy observation concerns the actual subject matter within their patent applications. Rather than an overwhelming emphasis on intricate hardware designs or specific sensor layouts—which might be the expected output of component optimization—their IP portfolio increasingly shows a strong lean towards protecting the *methodologies* themselves. This includes advanced mathematical constructs, sophisticated control algorithms, and bespoke thermal regulation strategies. It's as if the critical insight is no longer just in the physical implementation, but in the sophisticated software and processing layers that coax unprecedented accuracy out of these intentionally limited systems. From an engineering standpoint, this indicates a clear understanding that the true differentiator lies in the intelligent orchestration of precise inputs and outputs, rather than simply raw hardware capability. The enforceability and breadth of such method patents, however, remain a critical area of interest for a researcher.

Beyond initial precision, a significant portion of Bosch's intellectual property filings, by mid-2025, are focused on *adaptive compensation and self-calibration mechanisms*. This is particularly intriguing because, within such confined measurement domains, the ability to continuously self-correct for subtle environmental fluctuations or the inevitable, minute degradation of components becomes far more tractable. The patents often describe algorithms that enable the system to autonomously refine its performance, striving for sustained exactitude throughout its operational lifespan. While the ambition to maintain extreme precision over time is commendable, one might ask how much "adaptation" is truly possible without eventually requiring physical recalibration or component replacement. Is the IP truly about eliminating the need for intervention, or simply delaying it?

A particularly striking element within their IP filings relates to what one could term "coherence window" strategies. These patents frequently detail the creation of exceptionally short and stable optical pathways, meticulously designed to sustain a very high degree of laser coherence. The stated goal is to enable the practical deployment of highly sensitive interferometric measurement techniques—methods typically confined to controlled laboratory environments—into more varied, yet still limited, operational scenarios. The IP often extends to novel optical train geometries and specialized signal processing algorithms specifically engineered to exploit this sustained coherence for unparalleled accuracy within tight bounds. The critical inquiry, from a broader engineering perspective, centers on the genuine novelty of these "windows"—are they fundamentally new optical principles, or highly refined applications of existing ones, effectively carved out as distinct protectable domains?

Finally, an intriguing and somewhat less obvious area of intellectual property emphasis by 2025 involves the methodologies for *integrating and validating highly specialized third-party components*. Given the inherent focus on precise operation within reduced measurement ranges, it seems Bosch is patenting the very protocols for how they collaborate with, and critically assess, their suppliers of bespoke optical and sensor elements. This isn't just about component specification; it extends to proprietary interfaces and unique performance verification techniques. This "co-innovation protocol" IP appears crucial for assuring the collective exactitude of the final product. While this strategy might indeed ensure robust and highly precise systems, one might ponder whether this level of proprietary integration could inadvertently restrict a supplier’s ability to work broadly in the market or limit their own independent innovation pathways.

Reduced Measurement Range Redefines Bosch Laser Precision - Ripples in the Laser Measurement Field

As of mid-2025, the laser measurement landscape is witnessing significant, subtle changes, or "ripples," emerging from the increasing focus on highly specialized, constrained-range optical systems. This evolving trend is fundamentally challenging long-established beliefs within the field that prized broad operational versatility, instead pushing for a critical re-evaluation of how ultimate exactitude is attained. It is becoming increasingly apparent that purposefully limiting a system’s scope can unlock unprecedented precision, compelling engineers to reconsider fundamental design trade-offs. However, while these advancements offer unparalleled accuracy for specific tasks, they simultaneously raise important questions about the long-term agility of such highly focused instruments and the wider industry’s responsiveness to shifting technological and market imperatives. This ongoing interplay between specialized technical excellence and evolving market needs is now a central topic for discourse in optical measurement.

The remarkable clarity of signals attainable across a confined measurement distance has seemingly pushed the boundaries of what's limiting precision. It appears that classical optical imperfections, previously significant hurdles, are now largely subdued. Consequently, by the middle of 2025, the intrinsic randomness inherent in light itself – particularly quantum shot noise – is emerging as the primary bottleneck for achieving absolute exactitude. This represents a noteworthy pivot in the engineering focus; the emphasis shifts from meticulously refining lens geometries and managing beam propagation to wrestling with the very granular nature of photons to eke out the last vestiges of certainty. One wonders if this newfound challenge will necessitate completely new detector architectures or simply more sophisticated signal processing at the quantum edge.

The narrow operational window is, perhaps surprisingly, fostering the practical application of what were once considered unstable or fleeting operating conditions within laser diodes for achieving high precision. It appears the inherent instabilities of these light sources are considerably dampened by the drastically abbreviated optical path length. This peculiar dampening effect then permits the exploration of innovative signal generation methodologies that, until recently, were relegated to theoretical discussions or highly controlled laboratory setups. While intriguing, the long-term reliability and robustness of systems relying on these 'tamed' transient modes remain a critical concern for real-world deployment; one must ensure that what is 'dampened' isn't merely shifted or prone to sudden, catastrophic failure under slight variations.

The considerably compact physical footprint of these laser measurement apparatuses is, as of mid-2025, paving the way for the widespread integration of advanced Micro-Electro-Mechanical Systems (MEMS) directly into the optical train. This offers an elegant solution to dynamic internal path adjustment and fine-tuning, seemingly sidestepping the cumbersome complexities of traditional mechanical alignment mechanisms. While the concept of miniaturization enabling new functionalities is not new, the sheer density and direct optical integration of MEMS arrays for continuous, agile path correction suggests a significant leap in system resilience and responsiveness. However, the inherent susceptibility of MEMS devices to environmental factors like vibration and temperature gradients—even within a controlled narrow range—demands rigorous scrutiny regarding their long-term stability and calibration drift.

Moving beyond straightforward adaptive compensation strategies, these specialized systems are, by mid-2025, incorporating sophisticated machine learning paradigms. The aim here is to intelligently anticipate and preemptively counter the subtle, gradual environmental fluctuations or the inevitable, protracted degradation of components. This effectively shifts the paradigm from merely reacting to detected errors to proactively maintaining peak precision within their tightly defined operational envelope. While this "predictive maintenance" for precision sounds promising, the efficacy hinges critically on the quality and breadth of the training data available for these models, and whether unforeseen, non-linear degradation paths can truly be captured and reliably compensated for without periodic human intervention or explicit re-calibration.

Maintaining the astonishing dimensional stability required within these abbreviated measurement ranges by the middle of 2025 seems to necessitate an extraordinary reliance on exotic low-thermal-expansion materials (LTEMs) for fundamental optical benches and structural mounts. Even the most negligible ambient temperature fluctuations appear to mandate the use of these highly specialized substrates to preserve nanometer-level positional consistency. While crucial for ultra-precision, one must consider the implications of such material choices on manufacturing scalability and overall system cost. Furthermore, even LTEMs exhibit some degree of thermal expansion, however minute, raising the question of whether the pursuit of absolute stability through passive means will eventually run into a fundamental, economic wall without increasingly complex active thermal control systems.

More Posts from patentreviewpro.com:

- →AT&T's Legal Battle with Broadcom Analyzing the VMware Perpetual License Dispute and Patent Implications

- →Patent Implications of China's 90% Dominance in Global Solar Polysilicon Production A Technical Analysis

- →7 Practical Applications for a Personal Humanoid Robot in Patent Development and Testing

- →Employee Invention Rights Navigating IP Ownership Terms in 2024 Employment Contracts

- →The Balancing Act Pursuing Passion vs Pragmatism in Trademark Innovation

- →7 Affordable and Reliable Database Options for Small Businesses in 2024